From 1906 to Major Championships

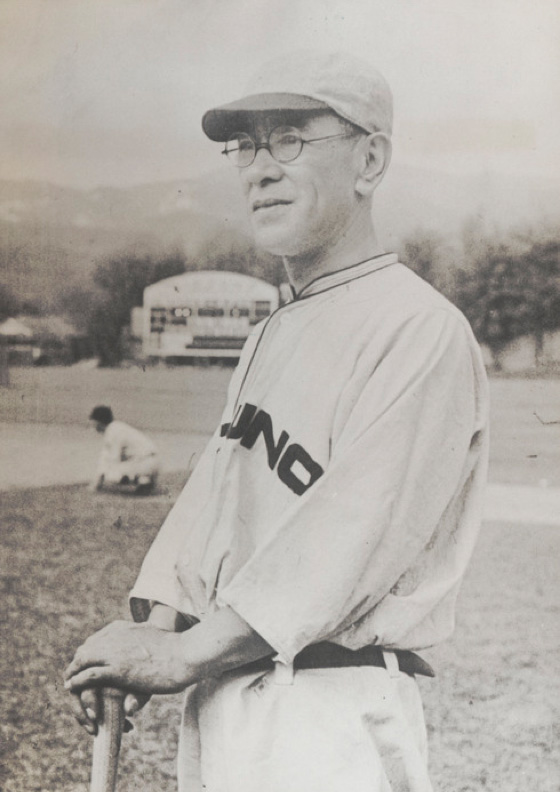

Rihachi Mizuno, a kimono shop worker from Osaka Japan, saw his first baseball game in Kyoto when he was 18 years old. He loved the game and in 1906 with his younger brother Rizo opened his own baseball equipment store selling western products. In 1913 the firm began to manufacture its own products in a quest to improve quality and performance.